Exploring the Role of Factory Solutions in Progressing Modern Engineering Solutions

Factory services are crucial in shaping contemporary design solutions - Precision aluminum casting. They bridge the void in between typical production strategies and the needs of contemporary markets. With innovations in automation and sustainability, shops are evolving to fulfill the needs of industries such as aerospace and automobile. This transformation questions about the implications for materials, procedures, and future advancements. What opportunities and challenges lie ahead for foundry solutions in this rapidly changing landscape?

The Evolution of Shop Providers in Design

The assimilation of computer-aided design (CAD) and simulation software program has actually revolutionized the style and manufacturing processes, enabling factories to generate intricate geometries with greater precision. Moreover, the change in the direction of eco-friendly practices has caused the adoption of greener innovations and reusing efforts within factories. As industries significantly focus on personalization and fast prototyping, foundry solutions have actually increased their capabilities, ensuring they remain crucial factors to the design landscape. This evolution highlights the shop's critical role in sustaining advancements across different markets, including automotive, aerospace, and power.

Trick Processes and Techniques in Modern Foundries

Modern shops use a variety of key procedures and techniques that enhance the effectiveness and top quality of steel casting. Amongst these, sand spreading continues to be widespread because of its convenience and cost-effectiveness. Making use of sophisticated modern technologies, such as computer-aided style (CAD) and computer-aided manufacturing (CAM), allows for accurate modeling and production, ensuring high precision in component measurements. In addition, financial investment casting is favored for creating complicated geometries with exceptional surface coatings.

Automation and robotics improve manufacturing speed and consistency while minimizing labor costs. Techniques like additive production are significantly incorporated to generate detailed molds and cores, thereby minimizing material waste. The application of thermal analysis help in enhancing casting procedures by predicting and controlling solidification habits. Jointly, these strategies and procedures exhibit exactly how modern-day foundries are adapting to meet the needs of contemporary design challenges, making certain remarkable product quality and operational performance.

The Relevance of Materials Selection in Shop Solutions

Picking the suitable products is important in factory solutions, as it straight influences the mechanical homes, resilience, and overall efficiency of the end product. Different materials have distinct features, such as tensile toughness, deterioration resistance, and thermal stability, which need to align with the designated application of the cast parts. Steels like light weight aluminum and steel are often selected for their strength-to-weight proportion, while alloys can enhance details efficiency qualities.

The choice process includes taking into consideration factors such as availability, cost, and manufacturability, which can significantly impact task timelines and spending plans. Additionally, developments in product science make it possible for the development of cutting-edge composites and specialized alloys that deal with arising engineering difficulties. Subsequently, a comprehensive understanding of product properties and their effects is necessary for engineers and foundry specialists to accomplish successful end results in their projects. This mindful choice process inevitably enhances the reliability and performance of completion products.

Factory Solutions in Aerospace and Automotive Applications

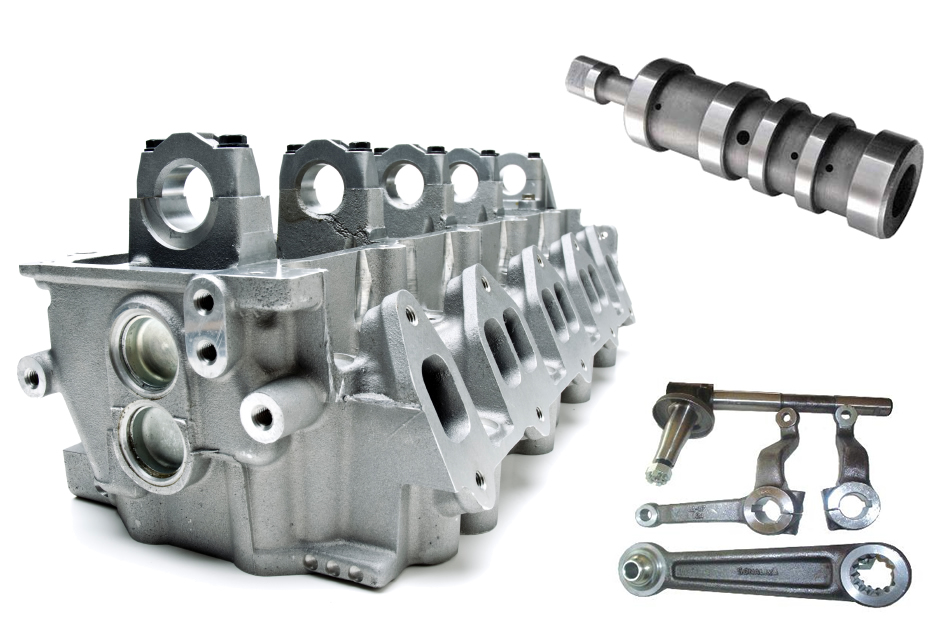

Shop solutions play a necessary role in the aerospace and automobile markets, where precision and efficiency are extremely important. These markets rely greatly on the production of complicated components that must satisfy strenuous quality standards and hold up against severe conditions. Foundries give essential services such as spreading, machining, and ending up, guaranteeing components are lightweight yet durable, crucial for boosting fuel performance and safety and security.

In aerospace, foundry services add to the production of wind turbine blades, engine elements, and structural parts, every one of which demand intricate designs and high-performance products. In the automobile sector, foundries provide engine blocks, framework components, and transmission instances, concentrating on resilience and weight decrease.

Advanced shop techniques, consisting of additive manufacturing and accuracy casting, are increasingly utilized to meet the specific requirements of these sectors. By supplying tailored remedies, factory solutions help drive advancement and maintain competitive advantages in the fast-evolving aerospace and auto landscapes.

Developments Driven by Foundry Capabilities

Various innovations in engineering are sustained by the innovative capacities of foundry solutions. These solutions allow the manufacturing of intricate geometries and high-performance materials that are necessary for contemporary applications. Additive manufacturing, generally recognized as 3D printing, has actually seen considerable developments with foundry techniques, allowing for the fast prototyping of complex styles. In addition, the ability to cast light-weight alloys has actually changed industries such as aerospace and vehicle, resulting in enhanced gas effectiveness and performance.

Shops are significantly integrating clever modern technologies, such as automation and data analytics, to enhance manufacturing performance and top quality control. These developments not only reduce waste yet additionally allow customization at scale, meeting the particular needs of customers. By leveraging sophisticated factory abilities, engineers can explore brand-new frontiers in item design and performance, like this ultimately driving progression across numerous sectors and establishing a foundation for future innovations.

Future Trends in Factory Solutions and Engineering Solutions

The future of foundry services is shaped by arising trends such as sustainable production techniques, which prioritize ecological responsibility. Automation and clever technologies are set to improve efficiency and precision, while enhancing customization and flexibility will meet the advancing demands of customers. As these patterns develop, they will certainly redefine the landscape of design solutions in the shop sector.

Lasting Manufacturing Practices

As sectors progressively focus on environmental responsibility, lasting manufacturing practices within factory services are becoming important to modern-day design options. These methods concentrate on lessening waste, reducing power consumption, and using environmentally friendly materials throughout the production process. By implementing methods such as recycling scrap steel and optimizing melting processes, factories can significantly decrease their carbon footprint. Additionally, the adoption of life process evaluations enables suppliers to assess the environmental influence of their items from inception to disposal. Working together with providers dedicated to sustainability further enhances the efficiency of these efforts. Eventually, embracing sustainable production not only aligns with global environmental objectives yet likewise cultivates advancement and competitiveness in the quickly developing design landscape.

Automation and Smart Technologies

While many industries are welcoming technological advancements, foundry services are experiencing a considerable makeover via automation and clever technologies. The combination of robotics and automated systems boosts manufacturing performance, reduces human error, and accelerates the manufacturing procedure. Smart innovations, such as IoT and AI, make it possible for real-time tracking and anticipating maintenance, which optimize operational efficiency and reduce downtime. These advancements facilitate data-driven decision-making, allowing foundries to respond quickly to market needs and enhance item high quality. In addition, automation minimizes labor prices and improves office security by taking care of hazardous tasks. As factory services remain to adopt these innovations, they are positioned to redefine engineering remedies, causing enhanced competitiveness and sustainability in the production sector.

Modification and Flexibility Fads

Arising trends in shop solutions significantly stress additional hints personalization and flexibility to satisfy unique consumer needs. This change reflects a wider need for customized engineering services that adjust to certain job demands and industry standards. Business are buying sophisticated technologies, such as additive production and electronic modeling, allowing them to generate customized parts efficiently and cost-effectively. Therefore, factories are relocating far from one-size-fits-all techniques, providing customers the capability to change designs and materials in real-time. Additionally, partnership in between engineering teams and factory services is coming to be extra integrated, cultivating development and accelerating time-to-market. This fad not just improves product performance however likewise sustains sustainability by decreasing waste via specific production processes.

Regularly Asked Questions

What Are the Normal Costs Connected With Shop Providers?

Typical costs linked with foundry services consist of material costs, labor charges, equipment use fees, and overhead costs - Aluminum Casting Company. These expenses can vary extensively based upon job complexity, quantity, and certain demands of the design option included

How much time Does the Foundry Refine Generally Take?

The factory process normally takes anywhere from numerous weeks to a few months, relying on elements such as intricacy, product demands, and production quantity, which can significantly influence timelines and overall project shipment.

What Industries Benefit Most From Factory Providers?

Industries such as automotive, aerospace, and construction benefit considerably from foundry solutions. These markets depend on accuracy casting and steel fabrication to produce intricate parts, improving item efficiency and functional performance in their particular applications.

What Certifications Should Factories Have?

Factories ought to have qualifications such as ISO 9001 for high quality administration, ISO 14001 for ecological monitoring, and certain market certifications like AS9100 for aerospace or IATF 16949 for vehicle, making certain compliance and quality control.

Exactly How Do Foundries Ensure Quality Assurance in Their Procedures?

Factory solutions are necessary in forming modern design options. As engineering disciplines have progressed, the role of shop solutions has changed significantly to meet developing market needs. As industries increasingly prioritize modification and fast prototyping, factory services have actually broadened their abilities, guaranteeing they stay necessary contributors to the design landscape. As sectors progressively focus on ecological obligation, lasting manufacturing practices within foundry services are ending up being crucial to modern-day engineering remedies. Additionally, cooperation between engineering teams check my reference and foundry services is coming to be more integrated, promoting advancement and increasing time-to-market.